HVAC sector to drive demand for OEM insulation

PUNE, India, 18 April 2022: With increasing urbanisation and industrialisation bolstering growth of developing regions, applications in automotive, consumer appliances and HVAC sectors have seen a rapid uptick, posing a direct impact on the demand for OEM insulation. According to a new research report by Future Market Insights, an ESOMAR-certified market research and consulting company and a member of Greater New York Chamber of Commerce, the global OEM insulation market is expected to reach a market value of over USD 19,500 million by the end of 2028, growing at a CAGR of 4.5% during the forecast period.

There has also been a significant increase in the construction projects globally in residential and commercial sector, which depicts leading growth of HVAC systems in the global OEM insulation systems, Future Market Insights said. HVAC systems cover a major part of the demand for OEM insulations, it pointed out.

The sector holds a dominating position in the global market, owing to the cost advantage and energy efficiency, Future Market Insights said, adding that the need for installation of HVAC systems has also called for considerable use of interior insulation systems to counter any external noise and adverse climatic conditions.

The rampant industrial requirements in developing regions, like Asia, shows a clear picture of the OEM insulation market’s potential for progress in the upcoming years, Future Market Insights said. The key factors expected to drive growth in the region include rising public and private investments in industrial, energy, oil & gas, petrochemical and food & beverage sectors; increased focus of local governments on enhancing industrial output; legislation of incentives to jumpstart the manufacturing sector, such as, development of Special Economic Zones (SEZs), industrial corridors, and industrial clusters and provision of subsidies and tax cuts for manufacturing groups and industrial corporations, Future Market Insights added.

Among the leading countries in Asia, India is expected have a foremost role to play in the global OEM insulation market, Future Market Insights said. According to the regional forecast, India is expected to grow at a CAGR of 5.6% during the forecast period, it said. However, in terms of market value, North America being a highly developed region, holds the largest market value by the end of 2028, it added.

The global market for natural and eco-friendly insulating materials is projected to have a highly lucrative market, Future Market Insights said. The move is in response to the upgradation of manufacturing techniques taking place. In order to gain competitive edge over the other and to reap the maximum benefits, market players are channelising their efforts to develop value-added products with increased efficiency, Future Market Insights said. Inclination towards the trend of eco-friendly insulation is one of such moves, it said, adding that many players are also a part of various collaboration activities, which enables the market player to adopt competencies and further drive the market.

Some of the players mentioned in the report are Rockwool Group, BASF, Evonik, Paroc Group Oy, Owens Corning Insulating Systems, Saint-Gobain, Armacell International, Johns Manville Corporation, ACH Foam Technologies, Henry Company, Shannon Enterprises of Western New York Inc., Styrotech, Inc. and NCFI Polyurethanes. According to Future Market Insights, the projections may reveal many more trends that companies may look forward to, in order to surpass their competitors and bolster growth.

Hira Industries launches thermal insulation solution

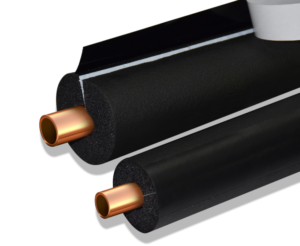

DUBAI, UAE, 15 February 2021: Hira Industries launched the Aerofoam NBR Lap Seal Tube, which the company described through a Press release as an effective and efficient thermal insulation solution that can be installed in various residential and commercial complexes to provide corrosion protection, whilst improving safety, efficiency and durability of the building.

Launched for the first time in the UAE market, the product is a pre-slit, closed-cell elastomeric thermal insulation tube, which is manufactured with a pre-installed adhesive that helps in reducing the use of additional adhesive by 90%, the company said. The overlap seals are particularly developed for mechanical, electrical and plumbing (MEP) contractors for a secure sealing and for reinsulating old and damaged pipes.

“At Hira Industries, our aim is to launch several new products and technologies in this year,” said Umesh Unni, General Manager, Hira Industries. “The focus will be to establish good customer relations and deliver cost-effective solutions to them. The launch of the Lap Seal Tubes is a reflection of our vision to expand our product base and cater to the ever-growing requirements of the insulation business.”

The Lap Seal Tube is much easier to install due to the pre-slit feature and the pressure-sensitive adhesive, reducing the installation time by more than 50%, the company claimed. Along with this, the company said, the aim of introducing the Lap Seal Tube is to provide a long-lasting insulation solution at a much lower cost in terms of the time and accessories used to install the product and the maintenance costs, as it does not require frequent maintenance and replacement. This feature of Tube makes it a unique proposition in the industry, setting it apart from existing products, the company asserted.

The fact that the product is manufactured in-house, the company said, facilitates quick bulk delivery and expert support for the HVAC&R industry, the company said. The Lap Seal Tube come with the guarantee of being able to last for more than a decade, as compared to the conventional insulation solutions that require frequent maintenance and replacement, making it the right solution for all insulation requirements at a much lower price, the company claimed. It is the perfect solution for a diverse range of insulation requirements, as the tube’s size can be customised to fit the pipes perfectly, while the pressure-sensitive adhesive overlay helps in an easy and quick adhesion, as compared to the other insulation solutions in the industry, the company said.

Unni said: “The tubes are made of high-grade-quality material and have an integrated structure, yet are economically priced, which makes them an attractive solution for all requirements. That is not all – keeping the environment in mind, we have used fume-free and clean materials to produce the Lap Seal Tubes. As a result, extra precautions are not required after installing the solution, which is extremely efficient in cooling systems, as they do not form condensation. We are committed to helping buildings increase LEED points, and the insulation of Lap Seal Tubes fulfills all LEED requirements to maintain a sustainable and green earth.”

Kingspan Insulation launches product for external ductwork applications

DUBAI, UAE, 5 January 2021: Kingspan Insulation launched the KDuct, which the company described in a Press release as catering to external ductwork applications.

DUBAI, UAE, 5 January 2021: Kingspan Insulation launched the KDuct, which the company described in a Press release as catering to external ductwork applications.

According to the company, the KDuct incorporates its pre-clad ductwork system, made of thermoset, fibre-free pre-insulated duct board with a heavy-duty outer jacket. The company described the product as ideal for external applications, plantrooms, risers, congested spaces and lightweight specifications. The KDuct, Kingspan claimed, offers high performance, rigid, closed-cell insulation core, manufactured with a blowing agent with zero Ozone Depleting Potential (ODP) and low Global Warming Potential (GWP). At the same time, it said, the panels are faced on both sides with an embossed aluminium foil. The new product line would provide ultra-strength and rigidness; cost-savings over traditional exterior ductwork; extra-low air leakage, which does not allow conditioned air to escape; and high-compressive strength, among several other benefits, the company said.

Sarmad Fakhri, Managing Director, Kingspan Insulation, said, “KDuct Ductwork system would help our customers to save extra cost and time due to its lightweight and single-fix properties.” Unlike the traditional approach to ductwork construction, which requires sections to be lagged with insulation, once installed, the KDuct panels are pre-insulated with a high-performance insulation core, the company said. This single-fix and lightweight design, the company added, reduces installation time and transfers the cost benefits to the building owners.